HYDRO DEMOLITION & CHEMICAL

HYDRO DEMOLITION

HYDRODEMOLITION IS AN ADVANCED TECHNIQUE THAT MTD COMPANY HAS MASTERED TO PERFECTION.

Hydrodemolition, often referred to as hydro blasting or water jetting, is a state-of-the-art concrete removal technique that utilizes high-pressure water jets to safely and efficiently break down concrete surfaces. Through the precise application of high-pressure water jets, we remove concrete layers while safeguarding the underlying structural integrity. This technique is perfect for bridges, highways, parking structures, and beyond, offering a tailored solution for even the most intricate projects.

Safe, efficient and precise concrete removal

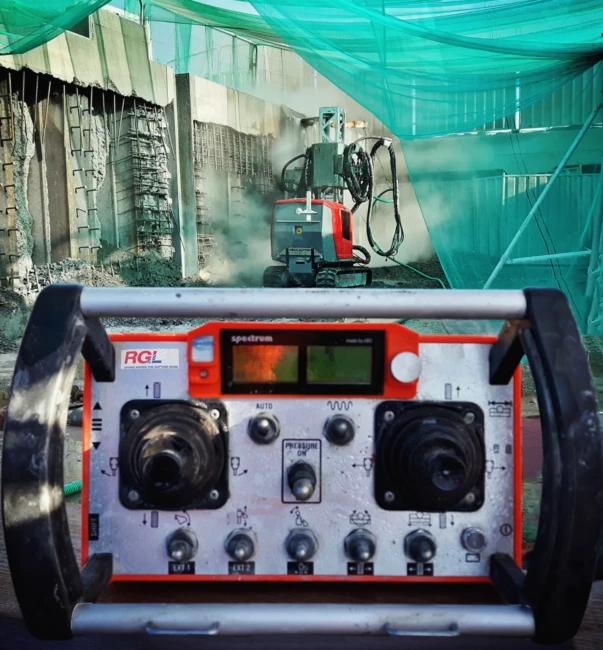

Hydrodemolition is a versatile and effective method of breaking concrete, which works by harnessing the power of ultra-high pressure water and focusing the resulting jet on the concrete to be removed. RGL provide both Robotic and Handheld Hydrodemolition services but often employ a combination of both depending on the specific requirements of the job.

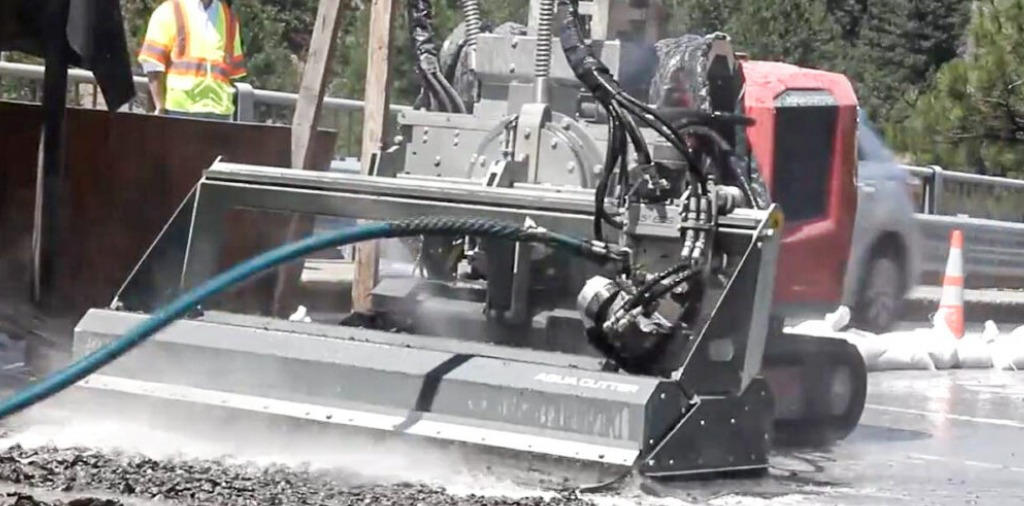

Robotic Hydrodemolition

Robotic Hydrodemolition is deployed when large areas of concrete need to be removed or in areas that are difficult for men to access. The MTD Hydrodemolition robots can be fitted with long-reach sections which reduces the need for working platforms or scaffolding. Most robotic equipment can be diesel or electrically powered making it suitable for use in a range of industrial environments.

- Roads, bridges, and runways

- Ports and quays

- Parking decks

- Canals and locks

- Dams, spillways, and turbines

- Pillars, piles, and columns

- Tunnels, aqueducts, and pipes

- Nuclear power plants

- Water treatment facilities

- Stadiums and warehouses

Hydrodemolition using Handheld lances

Where a high degree of accuracy is required or robot access is not possible, hand held jetting lances offer a safe and effective alternative. Although not as quick as a robot, a hand held lance operated by one of RGL’s experienced staff provides a precise and focused method of concrete removal.

Advantages of Hydrodemolition over traditional percussive methods

A water jet can be focused on the area of concrete to be removed. There is no percussive vibration and therefore, no micro cracking in the surrounding structure or the risk of “HAVS” to the operator. The process leaves any rebar clean and intact which is particularly cost effective in situations where the removed concrete will be resprayed/replaced.

The water jet breaks the removed concrete into gravel like particles that can be easily removed by mechanical shovel and the water used in the process can be contained, processed and disposed of on site in an environmentally responsible way.

COMPARING HYDRODEMOLITION WITH TRADITIONAL CONCRETE BREAKING METHODS HIGHLIGHTS THE CLEAR ADVANTAGES OF THIS INNOVATIVE TECHNOLOGY:

SURROUNDING DAMAGE

Hydraulic breakers or jackhammers, while effective in concrete removal, often come at a price – the inadvertent damage inflicted upon the remaining structure. The precision of hydrodemolition ensures selective removal, leaving the surrounding structure largely untouched.

PRECISION CONTROL

Hydraulic breakers and jackhammers lack the precision and control required for optimal and precise concrete removal. In contrast, Hydrodemolition provides operators with superior control, allowing for meticulous and targeted concrete removal.

SAFE AND EFFICIENT

Hydrodemolition is not only exceptionally safe and efficient but also offers a significant productivity advantage. Just one robot can accomplish the work of up to 25 jackhammer operators, dramatically reducing costs and increasing project output while mitigating safety risks. The process significantly reduces noise and eliminates silica dust exposure.

SELECTIVE REMOVAL

MTD Hydrodemolition services excel in selective concrete removal. Unlike traditional methods, hydrodemolition precisely targets concrete layers while safeguarding the integrity of embedded rebar. This meticulous approach not only preserves structural reinforcement but also prepares the surface for optimal bonding between old and new concrete. The result is a seamless interface between the two materials, ensuring long-term durability and structural integrity, while reducing the need for costly repairs.

REDUCED MICROFRACTURING

Unlike conventional methods, hydrodemolition’s precise, high-pressure water jet stream does not cause micro-cracks in the remaining structure. This crucial distinction ensures that any repairs conducted following hydrodemolition are built upon a foundation of structural integrity and durability. The absence of microfractures guarantees that your repair work will be of the highest quality, resulting in long-lasting and resilient structures that meet and exceed industry standards.

FASTER PROJECT COMPLETION

By utilizing high-pressure water jets, we achieve unparalleled precision and speed, making hydrodemolition more than 25 times faster than mechanical jackhammering. This impressive efficiency translates into substantial time and cost savings for your project. Unlike traditional methods, hydrodemolition significantly reduces the need for additional manual touch-ups or repairs. The result? Faster project completion times, a streamlined workflow, and a substantial reduction in disruptions.