Industrial Mechanical Services

our awesome Services

01.

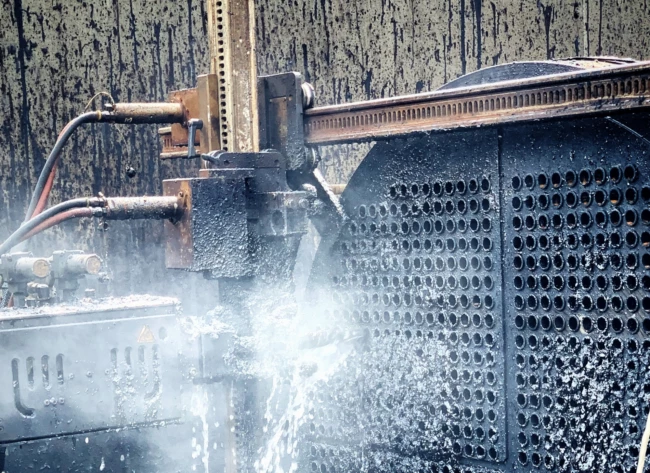

Clean heat exchangers work far more efficiently than dirty ones. Over time, the heating tubes & internal heat conducting surfaces of a heat exchanger can become contaminated. This contamination can act as an insulator with a resulting drop in efficiency.

02.

Tube bundle cleaning is the process of removing debris, scale, & other contaminants from the interior & exterior surfaces of tube bundles in heat exchangers, boilers, & other industrial equipment. This cleaning is essential for maintaining the efficiency and performance of the equipment.

03.

When the tubes of boilers or economizers become choked their efficiency is significantly decreased. MTD provides a safe, on-site tube cleaning service using only ultra-high pressure water which restores Boiler performance quickly and effectively.

05.

MTD has developed a range of equipment and methodologies that clear metal and/or concrete obstructions from blocked pipes as small as 95mm in diameter. These no-dig technologies have been successfully deployed in several situations and have avoided costly excavations and associated disruption.

06.

Once it has been established that the pipe blockage cannot be removed by conventional drain cleaning, The correct setup can be selected. An example of this is when a rig is placed into a pipe/sewer, fixed in place, and then the UHP cutting nozzles cut through the obstruction.

07.

Keeping pipework clean and unrestricted is essential to maintain product flow. Over time, Industrial pipe systems can effectively become smaller due to the build-up of scale or other deposits and this can negatively affect process speeds.

08

Regular and thorough cleaning of tank/mixing vessels is an essential part of tank husbandry. Whether it is to avoid contamination on product changeover, maintain mixing efficiency, or routine inspection it is important that the cleaning gets done quickly, and thoroughly.

09.

Ultra High-Pressure Water jetting is a highly effective technology for removing old coatings and/or corrosion from large steel surfaces. This method leaves a steel surface very clean with a good key for the immediate application of a new protective coating.

10.

11.

Ash and fused deposit buildup on furnace ceilings and walls create blockages that hamper heat and mass transfer. High-Pressure Water Jets are fast and effective at removing these deposits, improving plant efficiency. Even the hardest deposits are removed quickly and safely.

12.

Hazard abatement typically refers to the process of reducing or eliminating potential hazards in a particular environment. This can include addressing safety risks, health hazards, or environmental dangers. Hazard abatement may involve various strategies such as implementing safety protocols.

Why is heat exchanger cleaning and servicing important?

Clean heat exchangers work far more efficiently than dirty ones. Over time, the heating tubes and internal heat conducting surfaces of a heat exchanger can become contaminated. This contamination can act as an insulator with a resulting drop in efficiency.

With the rising cost of energy coupled with responsibility for safeguarding the environment, it is essential that contamination is kept to a minimum and this can only be achieved by using regular heat exchanger cleaning. You are best off using a heat exchanger servicing company.

Why use mtd heat exchanger cleaning services

As pioneers in the use of Ultra High Pressure water as an industrial cleaning medium, MTD have many years of experience and associated tooling for tackling the most arduous of heat exchanger cleaning tasks. MTD are an industry leading heat exchanger cleaning company. With several long term “rolling contracts” in place, MTD’s heat exchanger cleaning service provides their customers with regular (planned) heat exchanger cleaning as well as “one off” deep cleans for inspection, turnarounds or to restore efficiency.

Make sure you used a trusted Heat Exchanger Servicing Company. Should there be a requirement for our Heat Exchanger Cleaning Service, please feel free to contact us so we can talk through the requirement and plan to get things back to working as they should!

Improve Industrial Boiler/Economiser efficiency through effective cleaning

When the tubes of boilers or economisers become choked their efficiency is significantly decreased. MTD provides a safe, on-site tube cleaning service using only ultra-high pressure water which restores Boiler performance quickly and effectively.

Our Approach

We have developed water jet systems that can be deployed quickly and effectively in almost any industrial situation. Coupled with the equipment, we tailor our services to our customers’ requirements whether it is an emergency or part of a routine maintenance program.

We can offer 24/7 all-year-round site attendance as and when required.

Furnace cleaning

Ash and fused deposit build up on furnace ceilings and walls create blockages which hamper heat and mass transfer. High Pressure Water Jets are fast and effective at removing these deposits, improving plant efficiency. Even the hardest deposits are removed quickly and safely.

No dig obstruction removal

MTD has developed a range of equipment and methodologies that clear metal and/or concrete obstructions from blocked pipes as small as 95mm in diameter. These no-dig technologies have been successfully deployed in several situations and have avoided costly excavations and associated disruption.

Specific successful applications to date:

- Removal of concrete obstructions from pipes of various diameters where standard drain jetting methods have failed.

- Cutting out of foundation pile sections that have penetrated and blocked/part blocked drains/sewers

- Cutting out a section of Larson pile from 300mm flood plain overflow pipe and restoring flow

- Removing blockages/debris from inclinometer tubes without damaging the tube

In each case MTD carried out a full survey and developed bespoke methodology and associated equipment for each application.

Obstruction removal by water jet

Once it has been established that the pipe blockage cannot be removed by conventional drain cleaning, The correct setup can be selected.

An example of this is when a rig is placed into a pipe/sewer, fixed in place, and then the UHP cutting nozzles cut through the obstruction.

Once the cut is completed the obstruction can be removed using a vacuum or by using conventional jetting methods.

In other applications, conventional jetting methods can be used to remove the obstruction.

Industrial pipeline cleaning

Keeping pipework clean and unrestricted is essential to maintain product flow. Over time, Industrial pipe systems can effectively become smaller due to the build-up of scale or other deposits and this can negatively effect process speeds.

Over recent years, RGL has developed techniques for cleaning and deblocking pipework using only water albeit at high or ultra-high pressure. This means that pipework can be quickly restored to its original internal diameter without the need for replacement or the use of harmful chemicals or abrasives.

Pipe Cleaning Techniques for Various Industries

To date, we have successfully deployed our pipe cleaning techniques in a diverse range of industries such as oil refineries, chemical plants, food manufacturing factories and many more.

With a huge range of nozzles, centralisers and hose options amassed over the years, RGL is able to handle almost any pipe cleaning challenge at short notice whether it is a one off emergency or part of an ongoing maintenance program.

Steel Surface Preparation

Ultra High Pressure Water jetting is a highly effective technology for removing old coatings and/or corrosion from large steel surfaces. This method leaves a steel surface very clean with a good key for immediate application of a new protective coating.

There are no chemicals or abrasives used in this cleaning process so there is no dust or spent material to clear up. Furthermore, the waste water and debris can be simultaneously vacuumed up and contained for environmentally responsible disposal.

A cleaner, quicker method

The end result is a clean surface with the water jetting standard Wa2½ which meets the technical requirements of coating manufacturers for most maintenance and painting applications.

With many years of experience of this type of work, MTD has developed a range of remotely operated jetting robots which can operate on vertical as well as horizontal surfaces. These machines are hydraulically driven and can operate in zoned environment and on tanks that contain product.

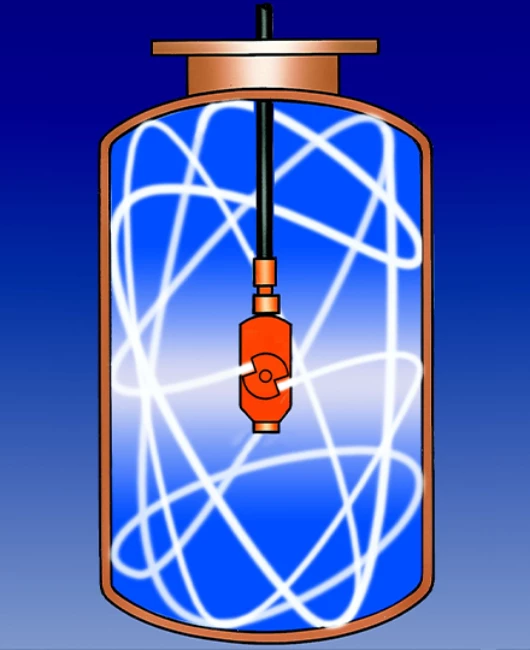

Internal tank and mixing vessel cleaning

Regular and thorough cleaning of tank/mixing vessels is an essential part of tank husbandry. Whether it is to avoid contamination on product change over, maintaining mixing efficiency or routine inspection it is important that the cleaning gets done quickly, thoroughly and above all, safely.

Using pressurised water

High/Ultra High Pressure Water is a very effective method of restoring cleanliness to tank internals. As well as cleaning tank sides, the powerful water jets will also clean agitator shafts, and blade surfaces. There are no chemicals or abrasives used and the only medium deployed is water allowing disposal through the tank owners separator/drainage system

No man entry options

Over the years, MTD has amassed a range of remotely operated equipment that can be inserted into the tank from outside without requiring the operators to enter the vessel, thus significantly reducing the associated risks. Our 3 dimensional tank cleaning heads are able to direct powerful water jets in all directions enabling them to reach all areas requiring cleaning.